Automated Logic Corporation - ALC

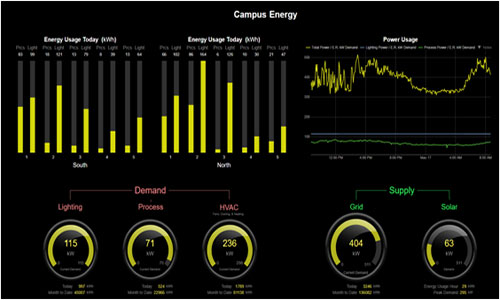

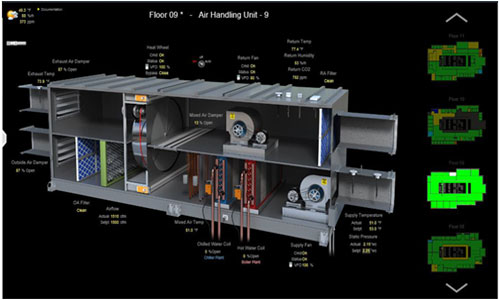

A proven, industry-leading system, the WebCTRL® building automation system gives you the ability to fully understand your operations and analyze the results with tools that make sense to you. It converts the BMS to a repository of all operating data and information related to your building. Whether it is temperature history, utility metering, trend data or comfort measurement, your WebCTRL system effectively packages the information you need for management of your facilities.

The WebCTRL® system is much more than a simple building automation system. It is a powerful web-based building automation platform with software tools that help you keep occupants comfortable, manage energy conservation measures, identify key operational problems and analyze the results. And, best of all, this can all be done anytime/anywhere, through a variety of Internet devices, from desktop PCs to web-enabled cell phones.

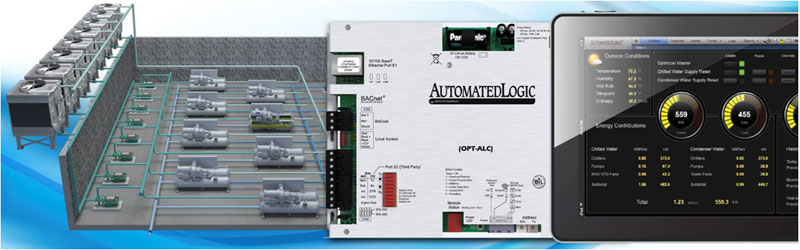

WebCTRL systems support major communications protocols, including BACnet, LonWorks®, Modbus® and SNMP. With its ability to run on Java2-compliant server platforms such as Windows®, Redhat Enterprise Linux®, and Unbuntu, the WebCTRL system can operate with many JDBC-compliant databases, including MS Access®, MySQL, MS SQL Server, Postgre SQL and Oracle®. WebCTRL systems can easily share data with enterprise or third-party systems to accomplish a range of tasks.